ADDRESSING CLIMATE CHANGE

Navistar takes seriously our responsibility to address the challenges of climate change and to do our part to accelerate the movement toward sustainable mobility.

Two strategic areas – decarbonization and circularity – will help drive us there.

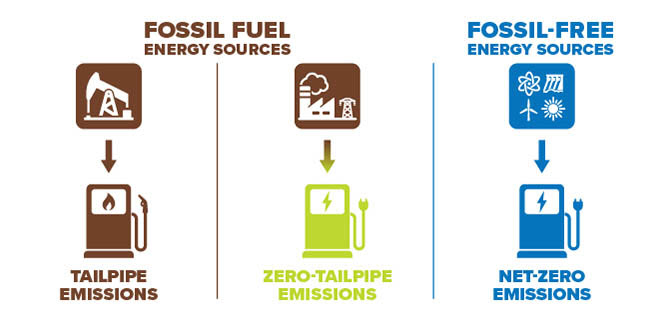

CLIMATE CHANGE AND SCIENCE-BASED TARGETS

Science-based targets (SBTs) are greenhouse gas reduction goals for businesses aligned with the Paris Climate Agreement. We plan to submit targets for Scope 1, 2, and 3 emissions to the Science-Based Targets Initiative (SBTi), an independent group that validates corporate targets, in 2023.

TOWARD A CIRCULAR ECONOMY

Circularity focuses on maximizing resources and minimizing waste. From raw materials to remanufacturing and recycling, we are committed to state-of-the-art sustainability stewardship across the lifecycle of our solutions. This includes evaluating energy and materials used in production, energy that fuels product distribution, and how customers use our products.

2022

2022

2021

2021

2020

2020

2019

2019

2018

2018

2017

2017

2016

2016

2016

2016

2015

2015

2014

2014